In the intricate world of industrial automation, where precision, reliability, and seamless integration are paramount, the ABB KUC755AE105 3BHB005243R0105 stands as a critical component. This specific module is a KU Control Unit, a central processing and communication node designed for ABB's renowned AC 800M High Integrity Controller family. These controllers are the bedrock of complex automation systems deployed in some of the world's most demanding industries, including oil and gas, power generation, chemical processing, and pharmaceuticals. The KUC755AE105 is not merely a piece of hardware; it is the intelligent core that orchestrates processes, executes control logic, and ensures the safe and efficient operation of entire plants. Its role is fundamental in transforming engineering designs and operational setpoints into real-world actions, making it an indispensable element within a sophisticated control system.

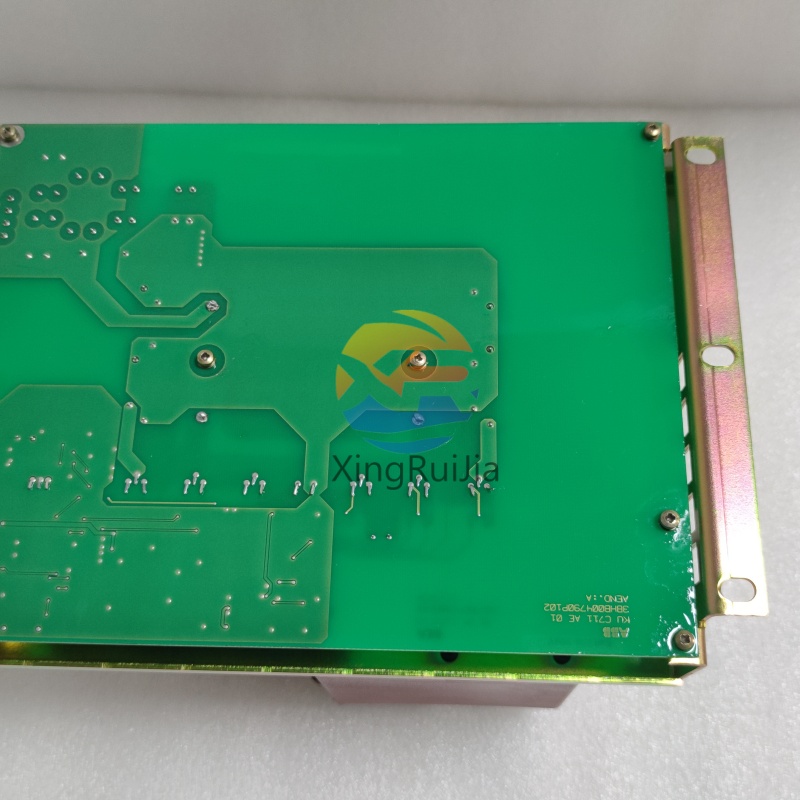

The part number 3BHB005243R0105 uniquely identifies this variant, specifying its memory configuration, processing capabilities, and firmware version. Understanding this module requires looking at the ecosystem it supports. It is designed to be installed into a dedicated rack or baseplate, where it interfaces with a wide array of other I/O and communication modules. This interconnectivity allows it to gather data from thousands of sensors—measuring temperature, pressure, flow, and vibration—and, in turn, send commands to actuators, valves, and motors. The robustness of the AC 800M platform, exemplified by the KUC755AE105, ensures that this data processing and command execution happen in real-time, with deterministic performance that cannot tolerate delay or failure. This reliability is what prevents costly downtime and hazardous situations in critical infrastructure.

The prowess of the KUC755AE105 lies in its advanced technical specifications and its role in enabling comprehensive industrial automation. Engineered for high availability and fault tolerance, this control unit often operates in redundant pairs. This means if the primary unit fails, the secondary unit takes over control within milliseconds without interrupting the running process, ensuring continuous operation. It features powerful processing capabilities to handle complex Proportional-Integral-Derivative (PID) control loops, sequential control, and advanced regulatory control schemes simultaneously.

Furthermore, its strength is amplified by its extensive communication protocols. The module seamlessly integrates into larger networked environments using industry-standard protocols like PROFIBUS, Modbus, and Foundation Fieldbus HSE. This connectivity is the linchpin of modern industrial automation strategies, enabling the vertical integration of the control layer with higher-level supervisory (SCADA) and plant information management systems (PIMS). By facilitating this flow of information from the field level to the boardroom, the KUC755AE105 helps enable data-driven decision-making, predictive maintenance, and overall operational intelligence. It transforms a collection of machinery into a cohesive, smart, and highly optimized production unit.

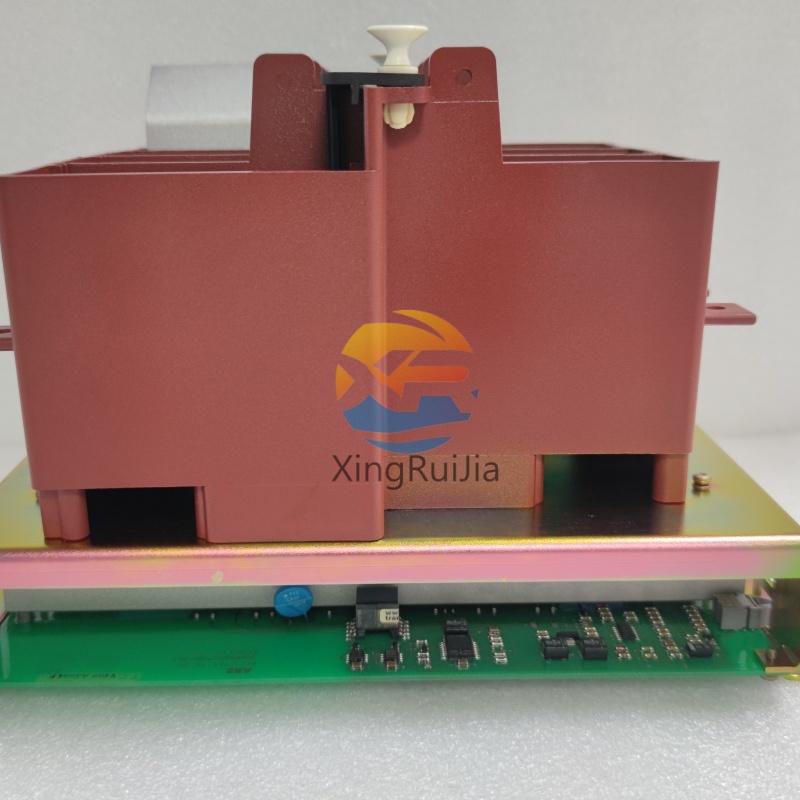

Beyond processing power and connectivity, the ultimate value of the ABB KUC755AE105 3BHB005243R0105 is measured in the reliability and safety it provides. In the industries it serves, a system failure is not an option. A shutdown in a power plant can leave thousands without electricity; a fault in a chemical processing unit can lead to dangerous situations. This control unit is built to the highest standards of quality and is designed to operate reliably in harsh industrial environments characterized by extreme temperatures, humidity, and electromagnetic interference.

Its design philosophy is intrinsically linked to functional safety. It can be integrated into safety instrumented systems (SIS) that are responsible for taking a process to a safe state in the event of an emergency. The reliability of its operation—its mean time between failures (MTBF)—is a carefully calculated and engineered parameter. This unwavering dependability ensures that protective functions are executed precisely when needed, safeguarding both human operators and multi-billion-dollar assets. This makes it more than a controller; it is a guardian of operational integrity.

In conclusion, the ABB KUC755AE105 3BHB005243R0105 is a quintessential example of the engineering excellence that underpins modern industry. As a vital node in a distributed control system, it is the workhorse that drives industrial automation forward. Its sophisticated technology, however, always serves a singular, crucial purpose: to deliver unmatched reliability for the most critical applications on the planet. It is a key component in building the efficient, safe, and intelligent industrial operations of today and tomorrow.