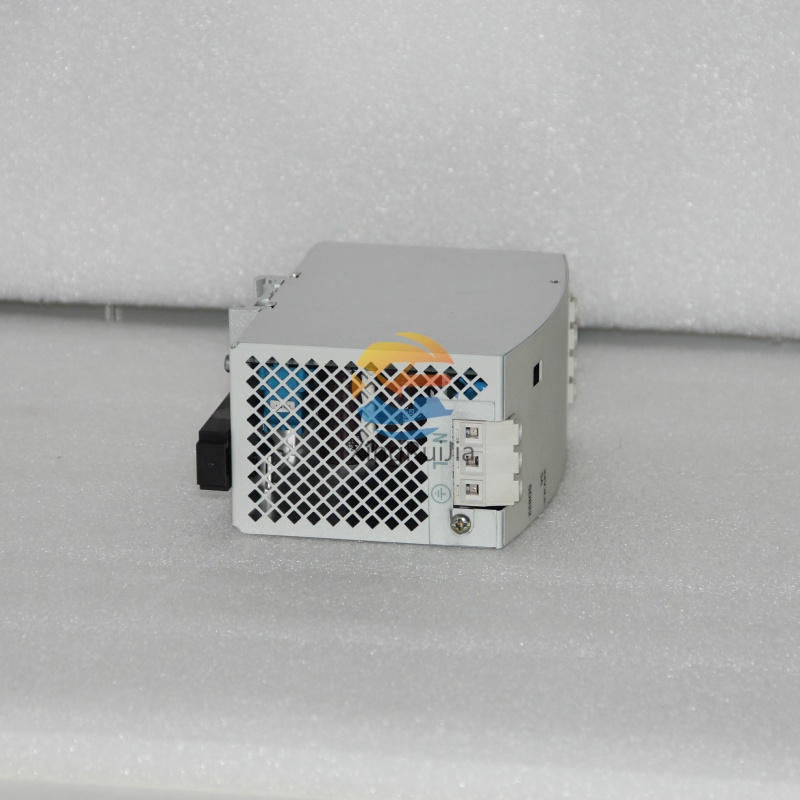

ABB SD822 - Industrial-Grade Safety Digital Input Module

Product Overview

The

ABB SD822 is a cutting-edge safety digital input module engineered for mission-critical industrial environments, where reliability, compliance, and real-time data accuracy are non-negotiable. As a key component of ABB’s safety automation portfolio, it’s designed to seamlessly integrate with ABB’s AC 800M controllers and System 800xA DCS, making it a top choice for industries prioritizing operational safety and regulatory adherence.

Ideal for applications requiring SIL (Safety Integrity Level) compliance, the SD822 delivers consistent performance in harsh conditions—from high-temperature manufacturing floors to dusty processing plants—ensuring uninterrupted monitoring of safety-critical signals.

Technical Specifications

|

Parameter |

Details |

|

Safety Certification |

SIL 2/3 compliant (per IEC 61508) |

|

Number of Input Channels |

8 isolated digital input channels |

|

Input Voltage Range |

24 V DC (19.2 V DC – 30 V DC) |

|

Input Current |

3 mA (typical) at 24 V DC |

|

Response Time |

≤ 1 ms (for critical safety signals) |

|

Operating Temperature Range |

-25°C to +70°C (-13°F to +158°F) |

|

Storage Temperature Range |

-40°C to +85°C (-40°F to +185°F) |

|

Mounting Type |

DIN rail mounting (EN 50022 standard) |

|

Communication Protocol |

PROFINET IRT / Modbus TCP (optional) |

|

Protection Rating |

IP20 (front panel); IP40 (with optional cover) |

Core Features & Benefits

1. Industry-Leading Safety Compliance

Certified to SIL 2/3 standards, the SD822 meets global safety regulations (e.g., OSHA, EU Machinery Directive), reducing risk of accidents and ensuring compliance with industry-specific mandates. Its dual-channel input design with built-in diagnostics adds an extra layer of protection against false signals.

2. Ultra-Fast Response Times

With a response time of ≤1 ms for safety signals, the SD822 enables real-time detection of anomalies—critical for stopping processes quickly in emergency scenarios, minimizing equipment damage and downtime.

3. Ruggedized for Harsh Environments

Built to withstand extreme temperatures (-25°C to +70°C), vibration, and electrical noise, the module maintains performance in challenging industrial settings (e.g., automotive assembly lines, chemical plants). Its conformal coating also protects against dust and moisture ingress.

4. Seamless Integration

Designed for plug-and-play compatibility with ABB’s AC 800M controllers and System 800xA, the SD822 eliminates complex setup steps. It also supports third-party systems via standard protocols (PROFINET IRT, Modbus TCP), making it easy to upgrade existing safety loops.

5. Advanced Diagnostics

Integrated self-diagnostic tools (e.g., short-circuit detection, channel fault monitoring) provide real-time alerts via the HMI, allowing maintenance teams to resolve issues proactively—reducing unplanned downtime by up to 30% (based on ABB customer data).

6. Energy Efficiency

Optimized power consumption (≤ 1.5 W per module) lowers operational costs, while its low-heat design extends component lifespan, reducing replacement frequency.

Key Applications

The ABB SD822 is trusted in safety-critical industries worldwide, including:

- Automotive Manufacturing: Monitoring emergency stop (E-Stop) signals, safety gates, and light curtains on assembly lines.

- Chemical & Pharmaceutical: Detecting pressure relief valve status and leak sensors in hazardous material processing.

- Heavy Industry: Controlling safety interlocks for industrial robots, conveyors, and milling machines.

- Oil & Gas: Monitoring flame detectors and emergency shutdown (ESD) systems in refineries and offshore platforms.

- Power Generation: Tracking safety valve positions and turbine interlocks in thermal or hydroelectric plants.

Integration & Compatibility

The SD822 works seamlessly with:

- ABB AC 800M controllers (for centralized safety logic)

- ABB System 800xA DCS (for plant-wide safety monitoring)

- ABB Ability™ digital platform (for remote diagnostics and predictive maintenance)

- Third-party PLCs via PROFINET IRT/Modbus TCP

Its modular design also allows for easy expansion—simply daisy-chain additional SD822 modules to increase input channel count without rewiring.

Technical Support & Services

ABB provides end-to-end support for the SD822 to maximize uptime and ROI:

- 24/7 Global Support: Access to ABB’s team of safety automation experts via phone, email, or live chat.

- Installation & Commissioning: Professional on-site services to ensure proper setup and compliance.

- Training Programs: Customized courses for engineers and technicians (in-person or online) on module configuration and troubleshooting.

- Warranty & Maintenance: 2-year standard warranty, with optional extended coverage and preventive maintenance packages.

- Obsolescence Management: Proactive alerts and migration plans to avoid disruptions from component end-of-life.

Why Choose the ABB SD822?

- Proven Reliability: Deployed in 10,000+ industrial sites worldwide with a 99.9% uptime rate.

- Future-Proof Design: Regular firmware updates ensure compatibility with evolving safety standards (e.g., IEC 61508 revisions).

- Cost Savings: Reduces maintenance costs via predictive diagnostics and lowers energy bills with efficient power use.

- Local Expertise: ABB’s global network of distributors and service centers ensures fast access to spare parts and support.

Ordering Information

To inquire about pricing, availability, or custom configurations for the ABB SD822:

- Contact your local ABB sales representative or authorized distributor.

- Specify “ABB SD822” and any additional requirements (e.g., PROFINET compatibility, extended temperature range).

- Explore recommended accessories:

-

- Communication cables (PROFINET/Modbus)

-

- Spare fuses and terminal blocks

Sweden

Sweden

.jpg)

.jpg)

.jpg)