Executive Summary: Bridging Legacy Control with Modern Networks

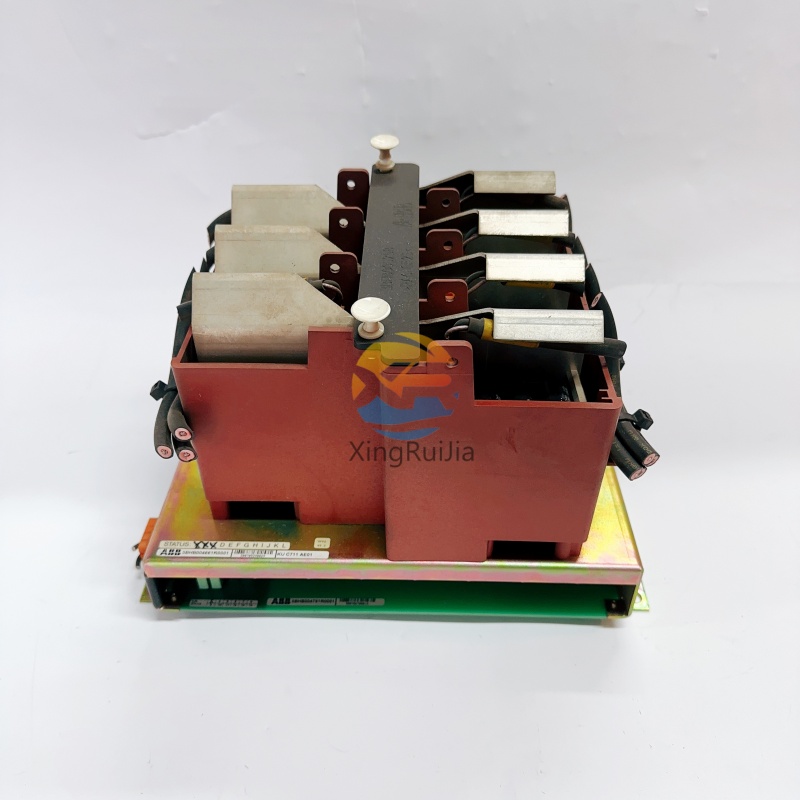

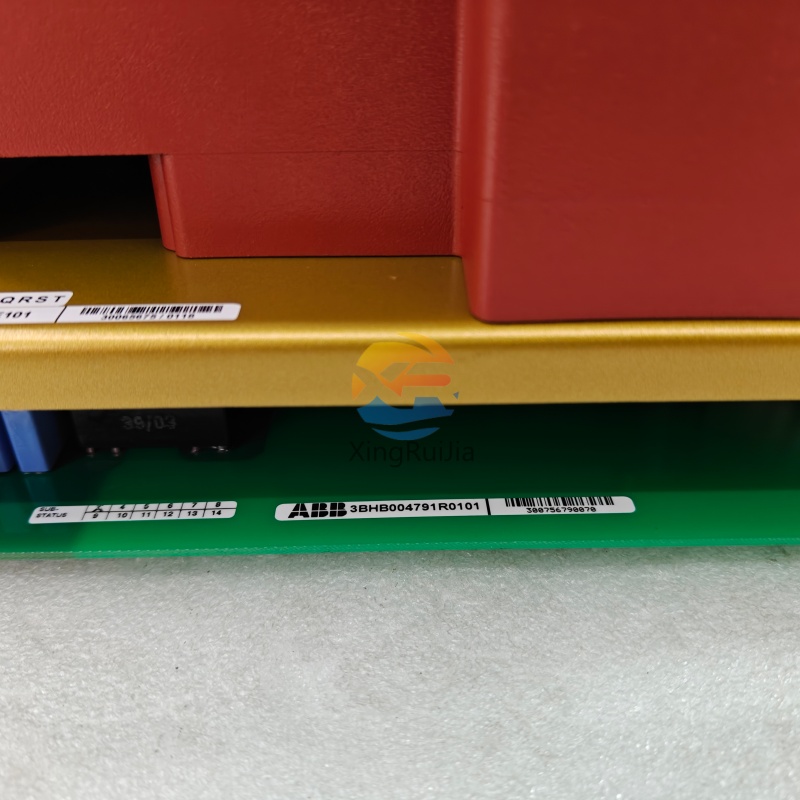

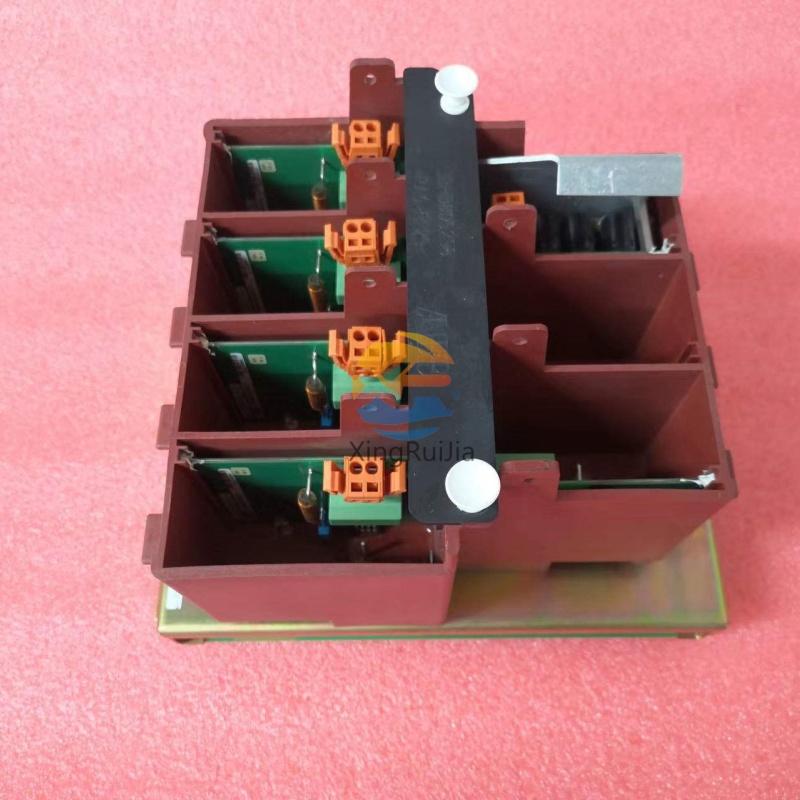

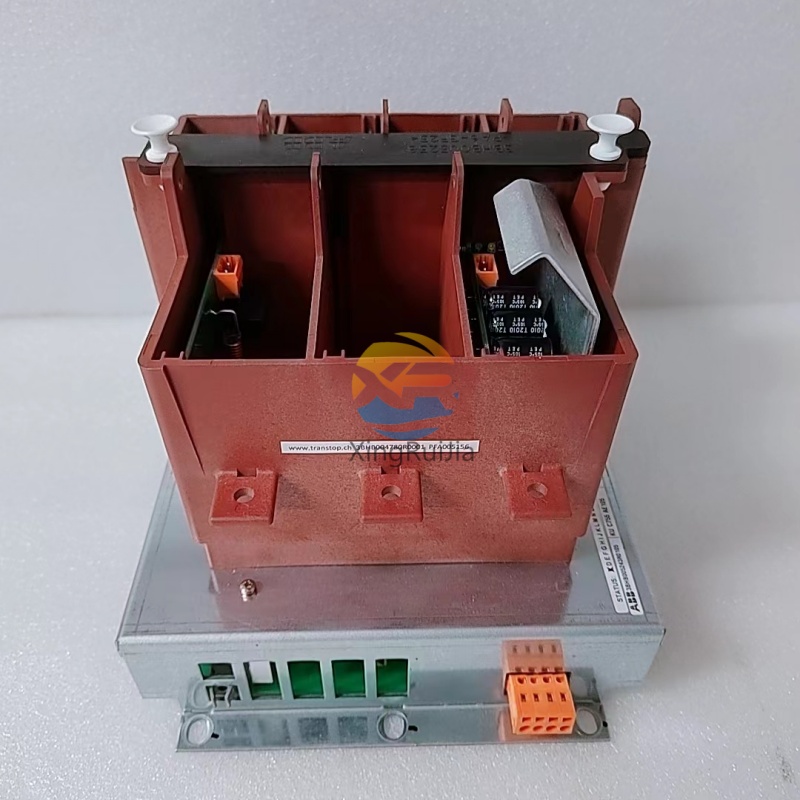

The ABB 3BHB004661R0101 KUC711AE101 represents a pivotal component within the framework of legacy industrial automation, serving as a robust and reliable Ethernet Interface Module for the widely deployed ABB Advant Controller 31 (AC 31) and Advant OCS (Open Control System). In an era where the Industrial Internet of Things (IIoT) and data-driven decision-making are paramount, this module acts as a critical gateway, enabling mature, yet highly dependable, control systems to communicate seamlessly with modern supervisory networks, SCADA systems, and enterprise-level data historians.

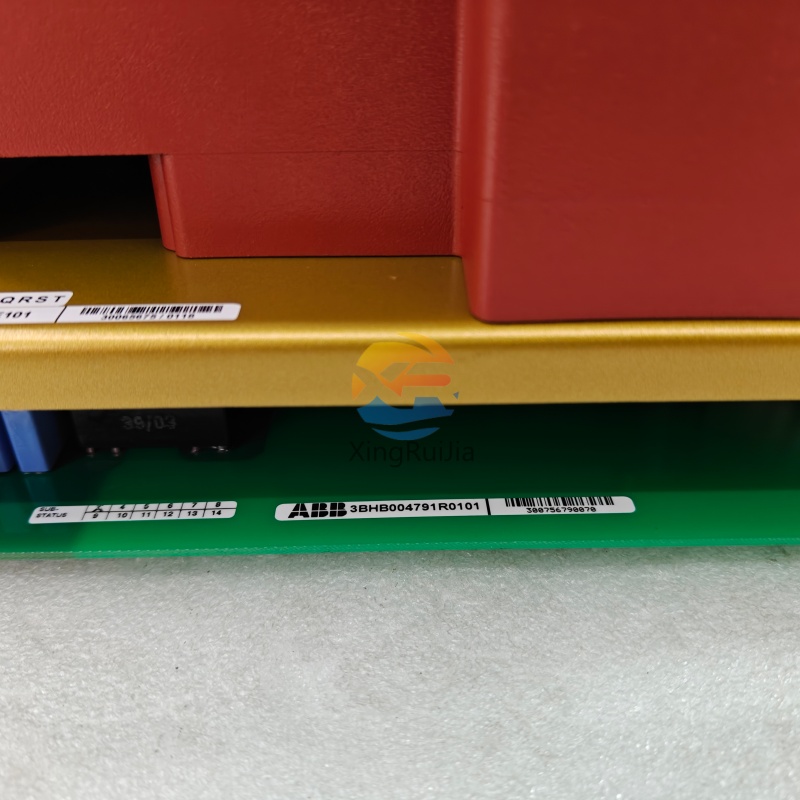

This specific part number, ending in R0101 and designated KUC711AE101, often signifies a specific hardware revision, firmware version, or an enhanced variant of the base KUC711AE model, providing improved stability or compatibility for certain system configurations. Its primary function is to translate the proprietary MasterBus 300 protocol of the AC 31 into standard Ethernet TCP/IP, effectively future-proofing critical infrastructure in industries like power generation, oil and gas, and chemical processing. This detailed product guide provides engineers, technicians, and procurement managers with an exhaustive technical reference and application manual for this essential communication module.

Detailed Technical Specifications: A Deep Dive into Capabilities

Understanding the nuanced specifications of the KUC711AE101 is the first step in ensuring correct integration and long-term system reliability.

General Product Identification

Hardware & Environmental Specifications

Communication & Network Performance Specifications

Software & Functional Specifications

Key Features and Unmatched Operational Benefits

The ABB KUC711AE101 is engineered to deliver specific advantages that translate directly into operational excellence and peace of mind.

-

Guaranteed System Compatibility and Seamless Integration: As a genuine ABB module designed specifically for the AC 31 platform, it guarantees flawless plug-and-play operation. This eliminates the integration risks, communication timeouts, and system instability often associated with non-OEM or counterfeit components.

-

Unlocks the Value of Data (IIoT Enabler): This module is the key that unlocks the vast amount of real-time data generated by the AC 31 controller. It enables:

-

Real-time Process Visibility: SCADA systems can display live process values, alarms, and equipment states on operator dashboards.

-

Historical Analysis and Optimization: Data historians can log production parameters, enabling trend analysis, root cause investigation, and process optimization.

-

Predictive Maintenance: Equipment health data can be fed into analytics platforms to predict failures before they occur, reducing unplanned downtime.

-

Robust Industrial Design for Maximum Uptime: Constructed with industrial-grade components and designed to operate within a wide temperature and humidity range, the KUC711AE101 is built for reliability. Its high electrical noise immunity ensures stable communication in electromagnetically noisy environments like switch rooms and factory floors, directly contributing to higher overall equipment effectiveness (OEE).

-

Deterministic and Predictable Communication: Unlike commercial networking gear, this module is designed for industrial control. It ensures that critical control data is transmitted with predictable latency and high priority, which is a fundamental requirement for stable and safe process control loops.

-

Simplified Network Architecture and Future-Proofing: By integrating the AC 31 into the standard Ethernet fabric of the plant, it reduces the need for complex and obsolete proprietary networking hardware. This simplifies infrastructure, lowers long-term support costs, and extends the viable life of the core control system by connecting it to modern tools and technologies.

Primary Applications and Critical Industries

The ABB AC 31 system, empowered by the KUC711AE101 module, is a cornerstone of automation in many mission-critical industries.

-

Power Generation & Distribution: Controls turbine auxiliary systems (lube oil, cooling water), boiler control sequences, switchyard equipment, and balance-of-plant operations in coal, gas, hydro, and nuclear power facilities.

-

Oil & Gas: Manages safety instrumented functions (SIF), controls offshore platform utilities, operates pipeline compressor and pumping stations, and automates complex processes in liquefied natural gas (LNG) plants and refineries.

-

Chemical & Petrochemical: Executes precise batch recipes, controls continuous processes in reactors and distillation columns, and manages critical temperature and pressure loops where reliability is non-negotiable.

-

Pulp & Paper Industry: Coordinates the high-speed, complex sequences of paper machines, controls chemical digesters, and manages coating and finishing lines.

-

Water & Wastewater Management: Automates pumping stations, filtration and reverse osmosis systems, chemical dosing, and activated sludge processes in treatment plants.

System Integration, Wiring, and Installation Guide

Compatible Controllers and Systems

The KUC711AE101 (3BHB004661R0101) is explicitly designed for integration with:

-

ABB Advant Controller 31 (AC 31) in all its variants.

-

The broader ABB Advant OCS (Open Control System) architecture.

-

It interfaces with the controller via the MasterBus 300 network.

Step-by-Step Installation & Wiring Procedure

Critical Safety Precaution: Always follow lockout-tagout (LOTO) procedures. De-energize the entire S800 I/O rack or AC 31 controller before installing or removing any modules to prevent electric shock and damage to equipment.

-

Physical Installation:

-

Locate an available slot designated for the communication module in your S800 rack or on the AC 31 base unit.

-

Ensure the module's guide rails are aligned correctly with the slot.

-

Gently but firmly slide the module into place until it is fully seated and the connector on the backplane is engaged.

-

Secure the module using the mounting screws or the locking lever, if present.

-

Network Connection:

-

Use a high-quality, shielded twisted-pair (STP) Ethernet cable (CAT5e or CAT6 is recommended) with the shield properly grounded at one end to prevent ground loops.

-

Connect the cable securely to the RJ-45 port on the front of the KUC711AE101 module.

-

Route the cable away from high-voltage power cables and sources of strong electromagnetic interference (e.g., variable frequency drives, large motors).

-

Hardware Configuration (DIP Switches):

-

The IP address is configured using the bank of DIP switches on the module.

-

Each block of switches corresponds to an octet of the IP address (e.g., Switches 1-8 for the first octet).

-

The "ON" position typically represents a binary '1', and the "OFF" position a binary '0'.

-

Consult the official ABB technical documentation for the 3BHB004661R0101 (e.g., the user manual or data sheet) for the precise DIP switch coding table, as the numbering and value assignment can be specific.

-

Software Configuration in Control Builder:

-

Within your ABB Control Builder M project, navigate to the hardware configuration of the respective AC 31 station.

-

Add the KUC711AE module to the appropriate slot in the hardware tree.

-

In the module's properties, ensure that the configured IP address (set via DIP switches) is correctly referenced in the software to maintain consistency.

Comprehensive Troubleshooting and Diagnostic Guide

A methodical approach to diagnostics is key to resolving issues quickly.

LED Status Interpretation

Common Fault Scenarios and Solutions

-

Scenario 1: No Communication from the PLC on the Network.

-

Cause: IP address mismatch, incorrect subnet mask, or faulty network configuration.

-

Solution: Verify the IP address set on the DIP switches matches the network settings in Control Builder and is on the correct subnet. Use a ping command from a computer on the same network to test basic connectivity.

-

Scenario 2: Intermittent Communication Drops.

-

Cause: Faulty or unshielded network cable susceptible to EMI; a failing network switch port; or a loose connection.

-

Solution: Replace the Ethernet cable with a known-good, shielded cable. Try a different port on the network switch. Reseat all connections.

-

Scenario 3: Module Not Recognized by Control Builder.

-

Cause: Improper installation (not fully seated in the backplane); faulty backplane; or an incorrect hardware configuration in the software project.

-

Solution: Power down the system, reseat the module firmly, and power up. Verify that the correct module type (KUC711AE) is selected in the correct slot in the Control Builder hardware configuration.

Why Source an Authentic ABB 3BHB004661R0101 Module?

The integrity of your control system hinges on the quality of its components.

-

Assured Performance and Long-Term Reliability: Authentic ABB modules are manufactured to exacting tolerances and subjected to rigorous environmental and lifecycle testing. This guarantees they will perform as specified for their intended service life, a claim that cannot be made for counterfeit parts.

-

Full System Compatibility and Warranty Protection: Using a non-OEM module can lead to unpredictable system behavior, communication errors, and even damage to other components. It will almost certainly void any remaining warranty on your control system. Genuine parts come with ABB's guarantee of compatibility and are backed by a warranty.

-

Safety and Compliance: In critical industrial applications, a faulty component can lead to safety incidents, environmental releases, or massive production losses. Authentic ABB components are designed and certified for use in such safety-critical and regulated environments.

-

Access to Technical Documentation and Support: Only with a genuine part number can you access the correct ABB technical manuals, firmware updates, and receive expert support from ABB or its authorized partners.

Frequently Asked Questions (FAQ)

Q1: What is the difference between the KUC711AE and the KUC711AE101?

A1: The suffix "101" in the functional type designation and the "R0101" in the article number typically indicate a specific hardware revision or variant. This could involve minor component changes, an updated firmware version pre-loaded, or a region-specific model. For all practical purposes regarding physical installation and base functionality, they are equivalent, but it is always best practice to replace a module with the exact article number specified in your system's Bill of Materials (BOM).

Q2: Is this module still available for purchase new from ABB?

A2: The KUC711AE101 is part of a legacy product line. While it may not be in active production, it is supported by ABB's legacy and spare parts division. Availability of new-old-stock (NOS) units can be limited. Reputable industrial automation parts suppliers, like ours, specialize in sourcing and providing fully tested and guaranteed refurbished or NOS units for these critical systems.

Q3: Can this 10 Mbps module function on a modern 100/1000 Mbps network?

A3: Yes. Modern network switches are backward compatible and use auto-negotiation. When you connect the KUC711AE101 to a Gigabit switch port, the switch will automatically downshift to communicate at 10 Mbps. The communication will be stable and reliable, albeit at the module's native 10 Mbps speed.

Q4: Do you provide a warranty and testing report?

A4: Absolutely. We understand the critical nature of these components. Every ABB 3BHB004661R0101 KUC711AE101 module we supply undergoes a rigorous testing procedure in a live AC 31 system to verify its power-up, communication, and diagnostic functions. We provide a certificate of conformity and a standard 12-month warranty on all our parts.

Q5: How do I confirm this is the correct part for my system?

A5: The best way to confirm is to check the part number printed on the existing module in your S800 rack or AC 31 controller. You can also cross-reference your system's electrical drawings or the Bill of Materials (BOM) from the original ABB Control Builder project file.

Conclusion: Your Strategic Partner for Legacy ABB Automation

The ABB 3BHB004661R0101 KUC711AE101 is more than just a spare part; it is an investment in the continuity, safety, and data accessibility of your industrial process. Maintaining your Advant OCS system with genuine, high-quality components is the most cost-effective strategy for avoiding catastrophic downtime.

As specialists in legacy industrial automation systems, we provide not just components, but solutions. We offer technical support to help you confirm compatibility and ensure a smooth integration process.

Contact us today via email or phone to request a specific quote for the 3BHB004661R0101, check current stock levels, and discuss your project requirements. Ensure the longevity and connectivity of your critical control assets with a guaranteed ABB solution.

Sweden

Sweden

.jpg)

.jpg)

.jpg)

Sweden

Sweden

.jpg)