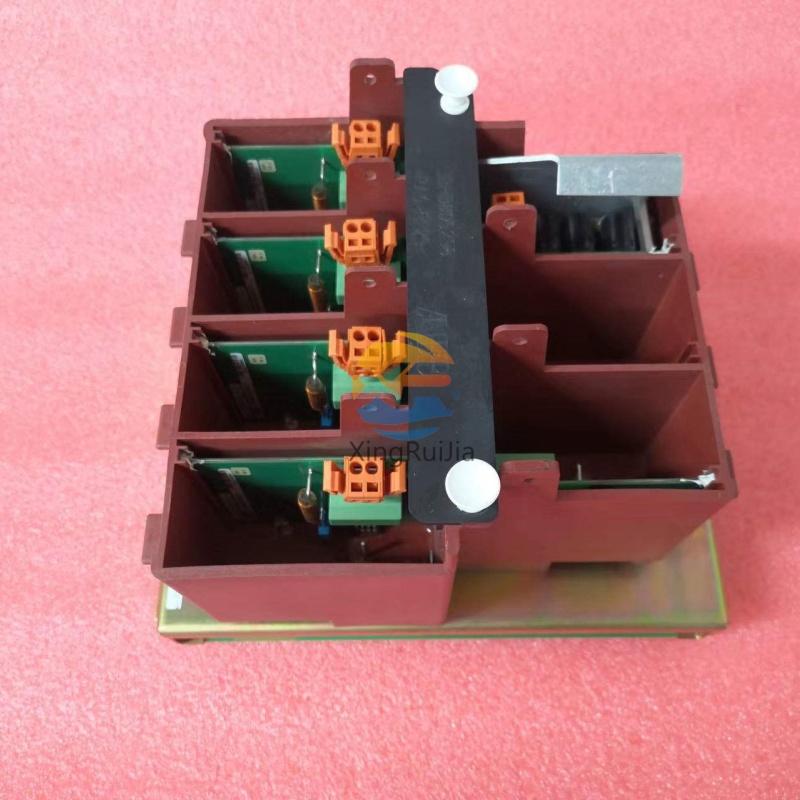

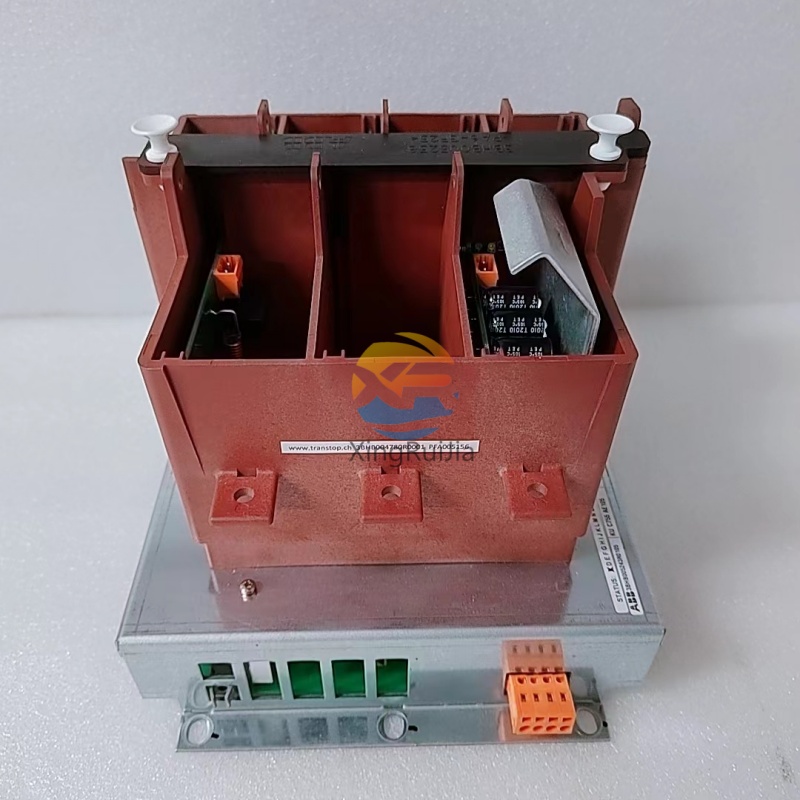

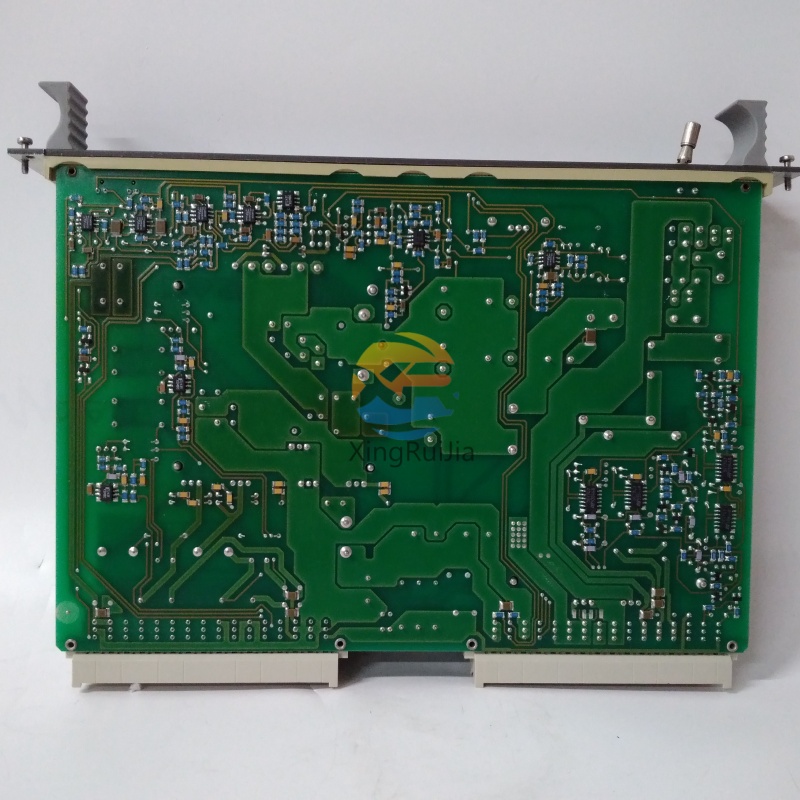

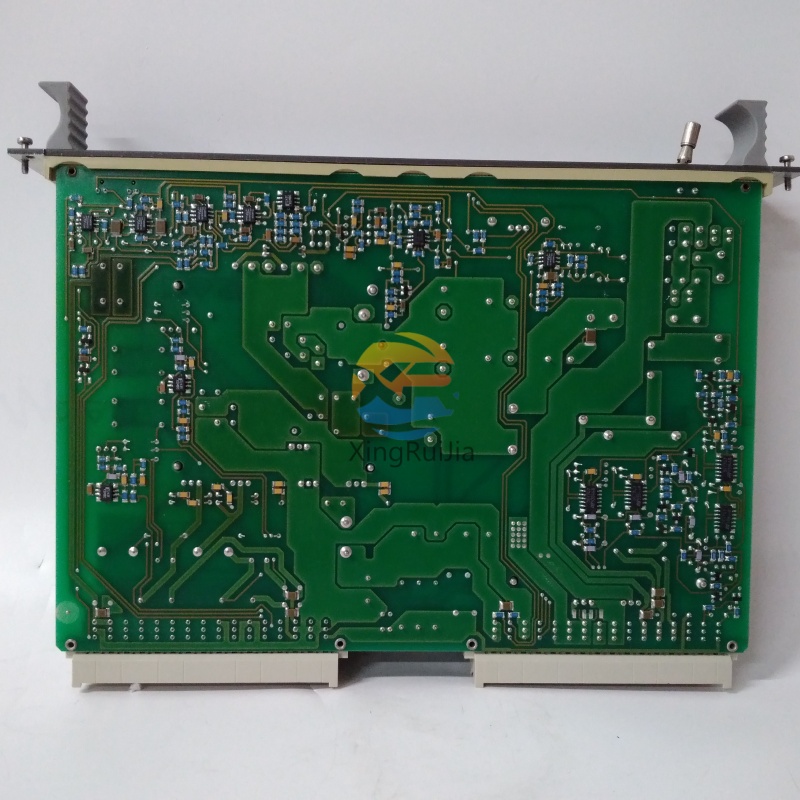

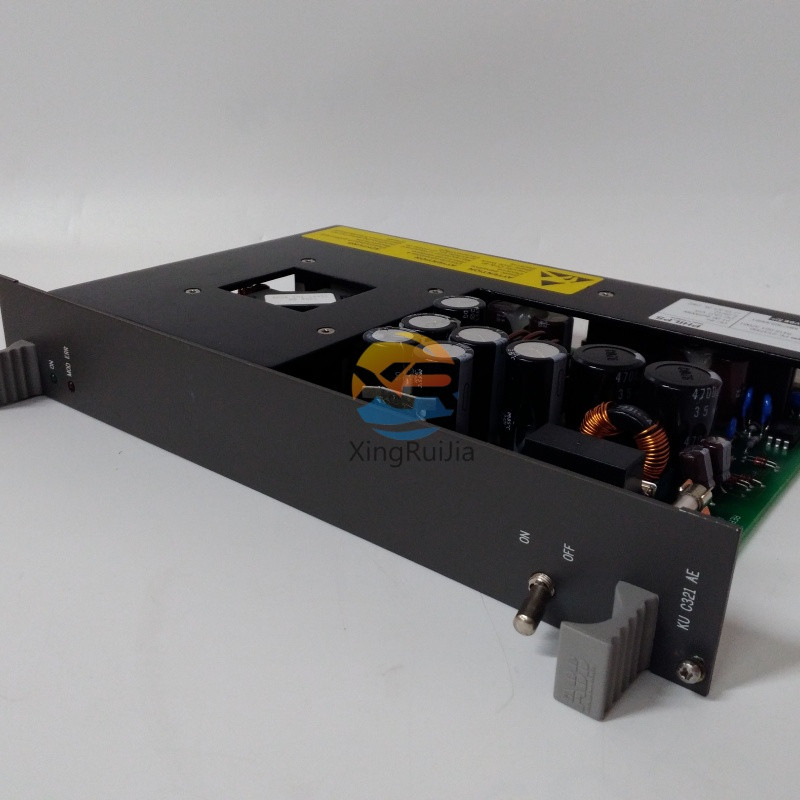

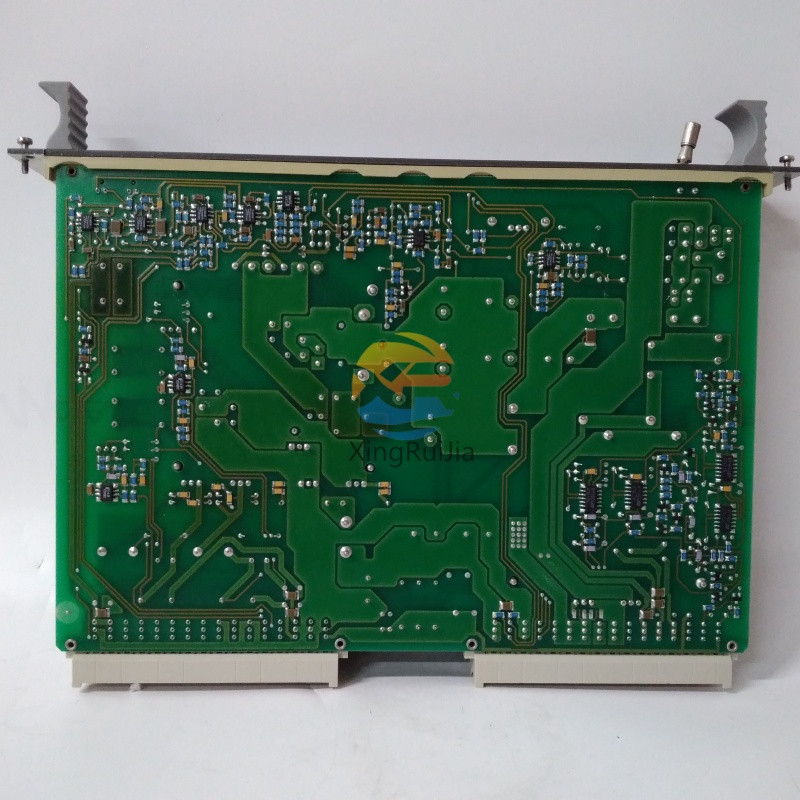

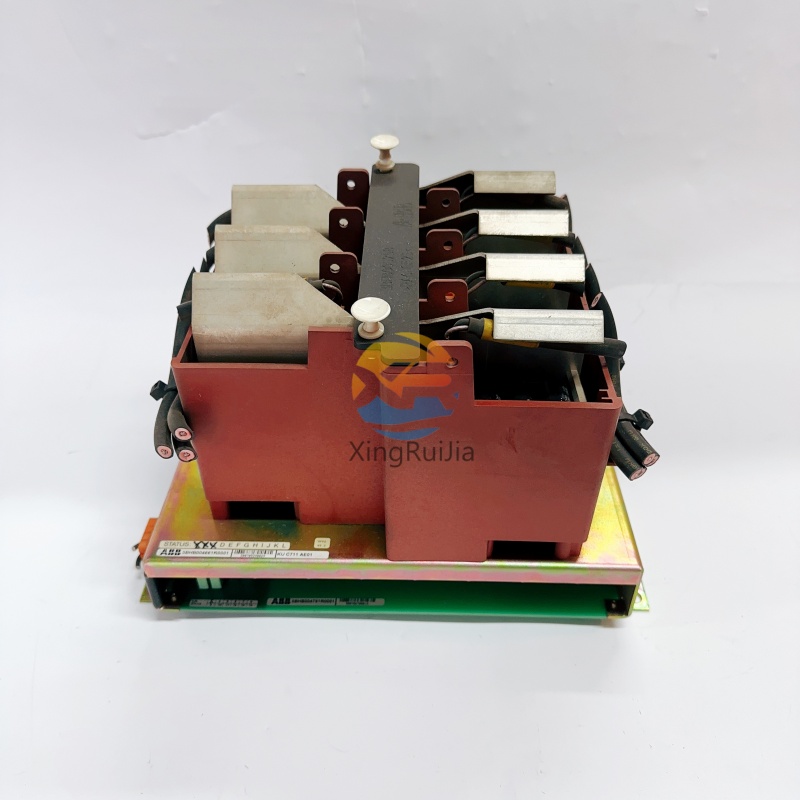

ABB KUC321AE HIEE300698R0001 CI871K PROFIBUS DP-V1 Communication Interface

Introduction: Bridging the Gap in Industrial Networks

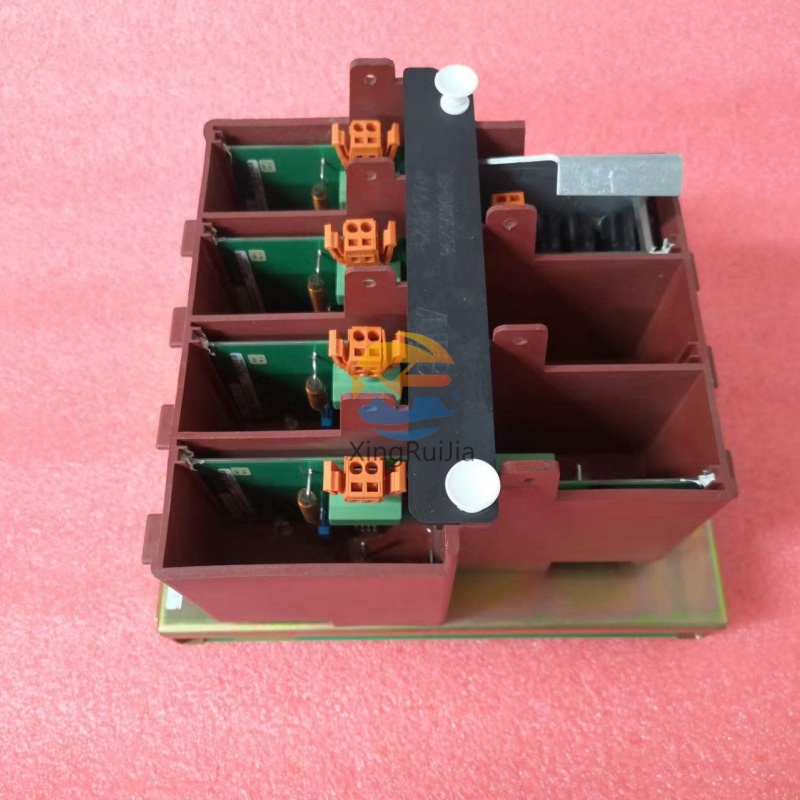

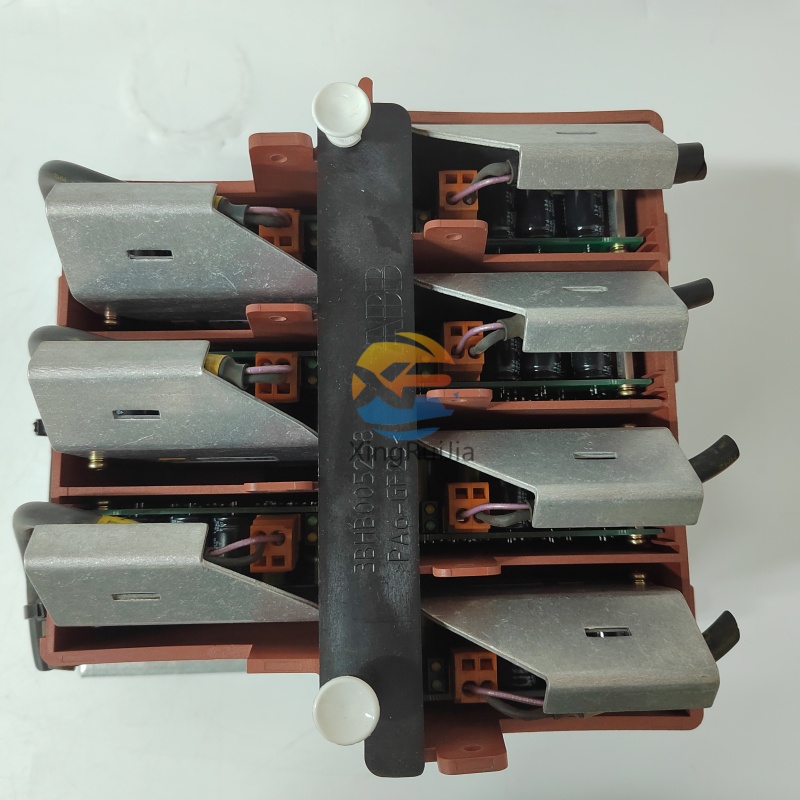

In the architecture of modern industrial automation, seamless communication between devices from different manufacturers and across various fieldbus protocols is not a luxury—it's a necessity. The ABB KUC321AE HIEE300698R0001, more commonly known as the CI871K module, is a critical component designed to perform this exact task with unmatched reliability. This device is a PROFIBUS DP-V1 Communication Interface, serving as a vital gateway between ABB's high-performance S800 I/O system and the widely adopted PROFIBUS network.

As part of the ABB Ability™ System 800xA and Advant Controller 800xA families, the CI871K enables a unified automation environment where data flows effortlessly from field devices to the control room. This page provides a exhaustive technical and commercial overview of the KUC321AE module, detailing its role, specifications, and why it remains an indispensable asset for system integrators and plant engineers worldwide.

Product Overview and Identification

-

Manufacturer: ABB

-

Core Model: KUC321AE

-

Alternative Designation / Article Number: HIEE300698R0001

-

Common Name: CI871K Communication Interface

-

Product Line: S800 I/O, System 800xA

-

Primary Function: PROFIBUS DP-V1 Slave Communication Interface

-

Key Application: Network Integration, Protocol Conversion, Distributed I/O Control.

The ABB KUC321AE module is a field-mounted communication interface that allows a cluster of ABB S800 I/O modules to appear as a single, sophisticated slave node on a PROFIBUS DP-V1 network. This enables a primary controller (a DP Master), which could be from ABB, Siemens, or any other PROFIBUS-compliant vendor, to read from and write to the S800 I/O points directly.

Key Features and Operational Benefits

The CI871K is engineered for robustness and ease of integration, offering a suite of features that deliver tangible benefits in a live industrial setting.

1. PROFIBUS DP-V1 Protocol Compliance:

The module supports the full DP-V1 standard, which includes not only cyclic data exchange but also acyclic communication for parameterization, diagnostics, and alarm handling. This goes beyond basic DP functionality.

-

Benefit: Enables more sophisticated data management, device configuration, and detailed diagnostic reporting from the S800 I/O station to the master controller, leading to improved maintenance and troubleshooting capabilities.

2. Seamless Integration with ABB S800 I/O:

The CI871K is designed to be mounted in an S800 I/O station, typically as the leftmost module. It connects directly to the internal TDM (Time Division Multiplexing) bus of the station, managing communication for up to 64 I/O modules (depending on the configuration and data volume).

-

Benefit: Provides a compact, distributed, and highly reliable I/O solution that can be placed close to the field devices, reducing wiring costs and improving signal integrity.

3. High-Speed Data Exchange:

The interface supports PROFIBUS baud rates up to 12 Mbps, ensuring fast and deterministic data transfer between the I/O and the master controller. This is crucial for time-critical control applications.

-

Benefit: Ensures rapid system response times, which is essential for closed-loop control, interlocking, and safety-related functions.

4. Comprehensive Diagnostic Capabilities:

The module features extensive self-diagnostics and status indicators (LEDs) for power, module health, and PROFIBUS network status. It can report faults related to itself, the internal TDM bus, and individual I/O modules.

5. Robust Industrial Design:

Built to withstand the rigors of industrial environments, the CI871K operates reliably in conditions with typical levels of EMI/RFI noise, vibration, and temperature fluctuations.

-

Benefit: High mean-time-between-failures (MTBF), ensuring long-term reliability in demanding sectors like power generation, oil & gas, and marine applications.

6. Flexible Configuration:

The module's parameters, such as PROFIBUS address and I/O configuration, are set via a dedicated configuration file (GSD file) in the DP Master's engineering tool. The actual mapping of S800 I/O channels is defined in ABB's Control Builder M software.

Detailed Technical Specifications

For engineers and technical buyers, here is a detailed breakdown of the specifications for the ABB HIEE300698R0001:

Primary Applications and Use Cases

The ABB KUC321AE CI871K is deployed in scenarios where interoperability between ABB I/O and third-party PLC/DCS systems is required.

-

Hybrid System Integration: Integrating ABB's high-quality S800 I/O with a non-ABB PROFIBUS Master (e.g., a Siemens SIMATIC S7 PLC) as the primary controller.

-

Distributed Control Systems (DCS): Acting as a remote I/O drop for a larger ABB System 800xA DCS, where the controller is an 800xA AC 800M controller with a PROFIBUS master module.

-

Plant Modernization and Migration: Retrofitting older systems by replacing legacy I/O with modern S800 I/O, using the existing PROFIBUS network infrastructure as the backbone.

-

Decentralized Control Architectures: Placing I/O clusters close to machinery (e.g., compressors, pumps, motor control centers) and connecting them via a single PROFIBUS cable to a central control room, simplifying cabling.

System Integration and Architecture

Understanding the role of the CI871K within a control system is fundamental to its application.

1. Physical Installation:

The module is installed in an S800 I/O base unit (rack), such as the TU847 or TU844. It occupies one slot and derives its power directly from the backplane. The PROFIBUS network is connected to its 9-pin D-sub port.

2. Network Topology:

On the PROFIBUS side, the CI871K becomes a node on a multi-drop RS-485 network. It must be assigned a unique PROFIBUS address (1-125). The network requires a master class 1 controller and is terminated at both physical ends of the cable.

3. Configuration Workflow:

-

Step 1 (PROFIBUS Master): The integrator imports the CI871K's GSD (Geräte Stamm Datei) file into the master's configuration software (e.g., SIMATIC Manager for Siemens). They define the module's PROFIBUS address and configure the I/O data structure (the layout of input and output bytes).

-

Step 2 (ABB Side): Using ABB's Control Builder M software, the engineer creates a matching configuration for the S800 I/O station. This involves defining which specific I/O channels (e.g., AI01, DO15) are mapped to the PROFIBUS data bytes defined in the master.

-

Step 3: The configuration is downloaded to the respective devices. The master controller now cyclically exchanges data with the S800 I/O via the CI871K gateway.

Why Choose the ABB KUC321AE? The Strategic Advantage

-

Proven Interoperability: The CI871K has a long history of successful integration with a vast array of PROFIBUS master systems, reducing project risk.

-

Leverages ABB I/O Quality: It allows you to utilize the high density, accuracy, and reliability of ABB S800 I/O modules even in a non-ABB controller environment.

-

Simplified Spare Parts Management: Standardizing on S800 I/O across a plant, regardless of the primary controller, simplifies training and spare parts inventory.

-

Future-Proofing: As part of the System 800xA ecosystem, this module is supported within a forward-looking platform, ensuring long-term availability and service.

Sourcing, Compatibility, and Lifecycle Support

The ABB KUC321AE HIEE300698R0001 is a mature but critically important component. When sourcing, due diligence is essential:

-

Authenticity: Ensure the supplier provides genuine ABB parts. Counterfeit modules can cause network failures and pose a safety risk.

-

Condition: Clarify if the unit is new, factory-refurbished, or tested-used. Each has different implications for warranty and expected lifespan.

-

Compatibility: Verify compatibility with your existing S800 I/O hardware (base units, power supplies) and firmware versions.

-

Documentation: Request the GSD file and relevant technical manuals if they are not readily available from ABB's website.

ABB provides long-term lifecycle support for its industrial components, and the CI871K is no exception. Support includes technical documentation, repair services, and migration advice.

Frequently Asked Questions (FAQ)

Q1: What is the difference between DP and DP-V1?

A: DP (Decentralized Peripherals) primarily handles cyclic I/O data exchange. DP-V1 adds acyclic services, allowing for parameterization, diagnostics, and alarm handling during runtime, making it more powerful for intelligent devices.

Q2: Can the CI871K act as a PROFIBUS Master?

A: No, the CI871K is strictly a Slave device. It allows an S800 I/O station to be controlled by an external PROFIBUS Master.

Q3: What is the GSD file, and where can I find it?

A: The GSD file is a device master data file that describes the capabilities of the PROFIBUS slave to the master's configuration tool. It can typically be downloaded from the ABB support website or provided by your ABB representative.

Q4: How many I/O points can one CI871K module handle?

A: The limit is not by points but by the data volume. The CI871K supports a maximum of 244 input bytes and 244 output bytes of process data. The actual number of I/O modules is limited by this data volume and the power capacity of the S800 base unit (typically up to 64 modules).

Q5: My system uses an ABB AC 800M controller. Do I need this module?

A: If your AC 800M controller needs to communicate with S800 I/O via PROFIBUS, it will require a PROFIBUS Master module (like the CI854). The CI871K would be used in a remote station where the AC 800M is the master. If the S800 I/O is local to the controller, it uses a different communication module (like the CI830).

Q6: Is this module compatible with PROFINET?

A: No, the CI871K is exclusively for PROFIBUS. For PROFINET connectivity, you would need a different interface module, such as the ABB CI873K.

Conclusion: The Essential Gateway for PROFIBUS Integration

The ABB KUC321AE HIEE300698R0001 (CI871K) is a masterpiece of interoperability engineering. It elegantly solves the common challenge of integrating best-in-class I/O subsystems into a heterogeneous automation environment. Its reliability, comprehensive diagnostics, and compliance with the PROFIBUS DP-V1 standard make it the go-to solution for system integrators who will not compromise on performance or data integrity.

For projects requiring a robust, distributed, and highly communicative I/O architecture, specifying the CI871K is a definitive step towards achieving a seamless, efficient, and future-ready control system.

Call to Action:

Need to integrate your S800 I/O with a PROFIBUS network? Contact us today for a competitive quote on the genuine ABB KUC321AE module. Our technical experts can provide configuration guidance, GSD files, and ensure you get the right component for your application's needs.

Sweden

Sweden

Sweden

Sweden