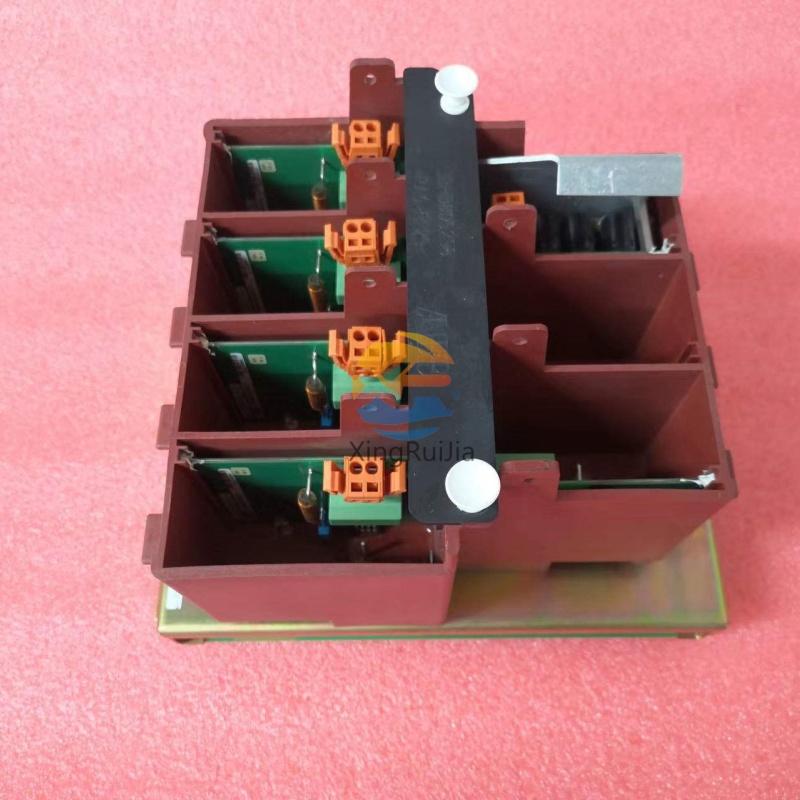

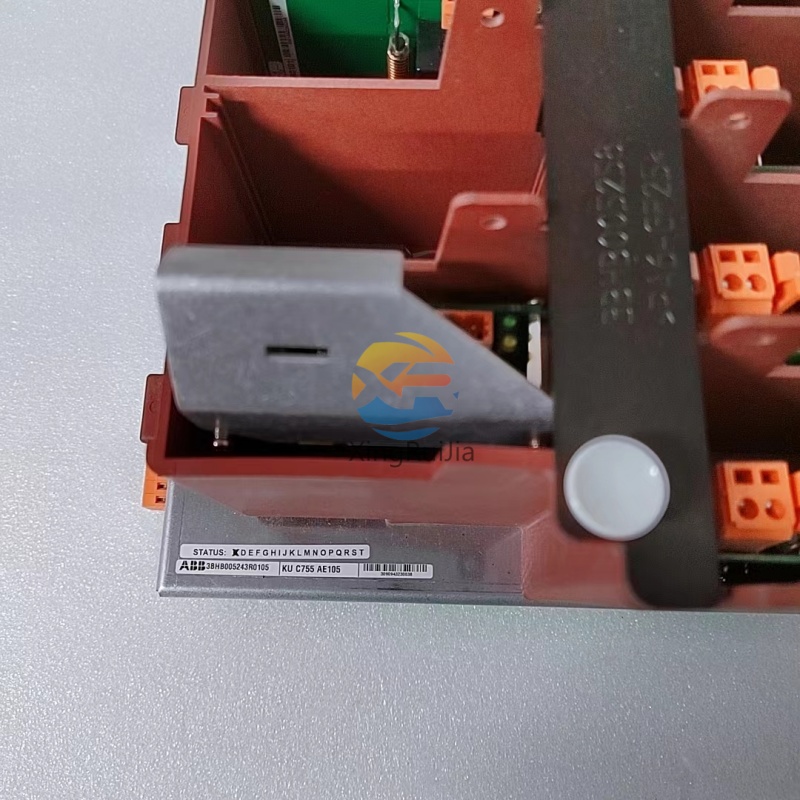

ABB KUC755AE117 3BHB005243R0117 | High-Performance Controller for Mission-Critical Automation

Introduction: The Apex of Control System Reliability

In the realm of industrial automation, the distinction between standard operation and performance lies in the core processing unit. For applications where microseconds matter and system failure is not an option—such as turbine control in a power plant or anti-surge control for a massive compressor—the controller is not just a component; it is the guardian of the entire process.

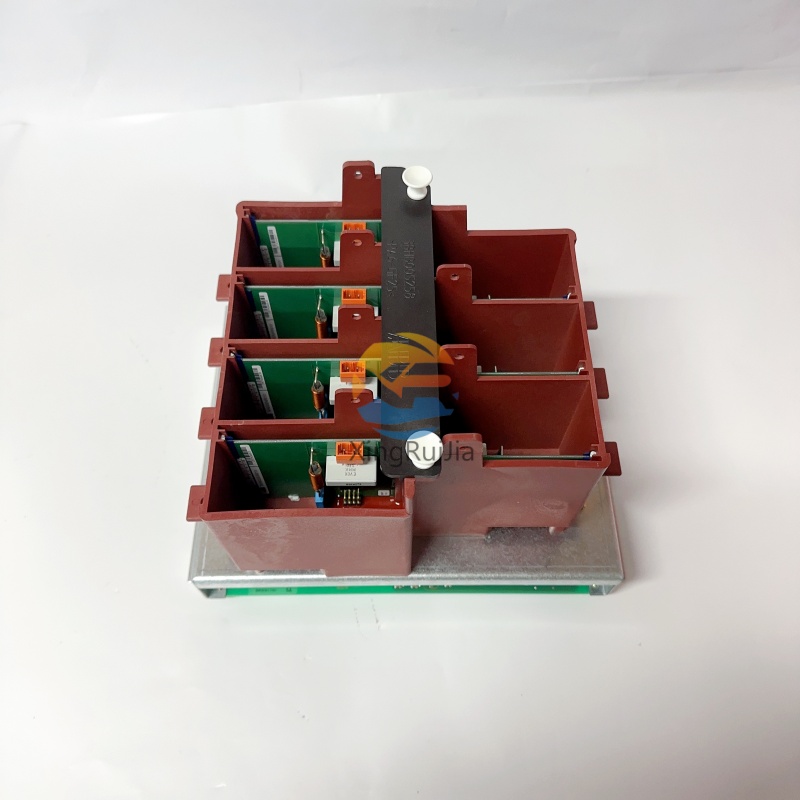

The ABB KUC755AE117 3BHB005243R0117 represents the pinnacle of this category. As a Central Processing Unit (CPU) within ABB's legendary Advant Controller 800xA family, this module is engineered for the most demanding control tasks imaginable. It is the brain of systems that manage immense kinetic and thermal energy, ensuring safety, optimizing efficiency, and guaranteeing unparalleled availability. This product detail page serves as the ultimate technical and commercial guide to this exceptional piece of industrial technology.

Product Overview and Identification

-

Manufacturer: ABB

-

Core Model: KUC755AE117

-

Full Order Code / Article Number: 3BHB005243R0117

-

Product Line: Advant Controller 800xA, part of ABB Ability™ System 800xA

-

Primary Function: High-Performance, Fault-Tolerant Process Automation Controller (CPU)

-

Key Application: Critical Turbine Control, Compressor Control, High-Speed Process Logic.

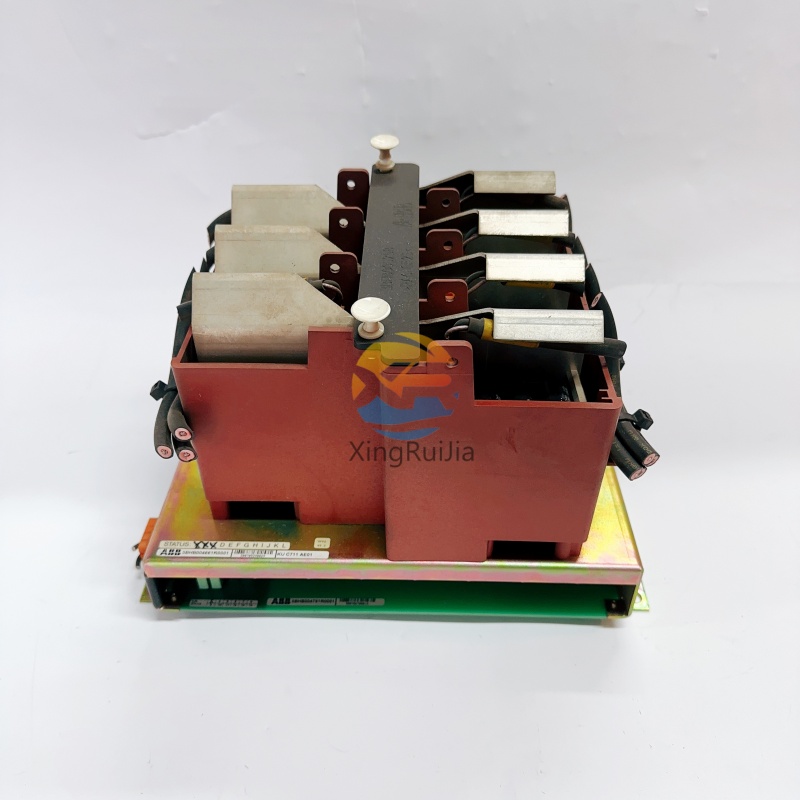

The ABB KUC755AE117 is more than a microprocessor; it is a complete control solution integrated into a single, robust module. It executes complex control algorithms with deterministic speed, managing thousands of I/O points across a distributed network. Its fundamental design philosophy is centered on high availability, featuring intrinsic support for redundant configurations that ensure continuous operation even in the face of a hardware fault.

Key Features and Operational Benefits

The KUC755AE117 is packed with advanced features that deliver tangible benefits in reliability, performance, and operational insight.

1. Deterministic, High-Speed Processing Engine:

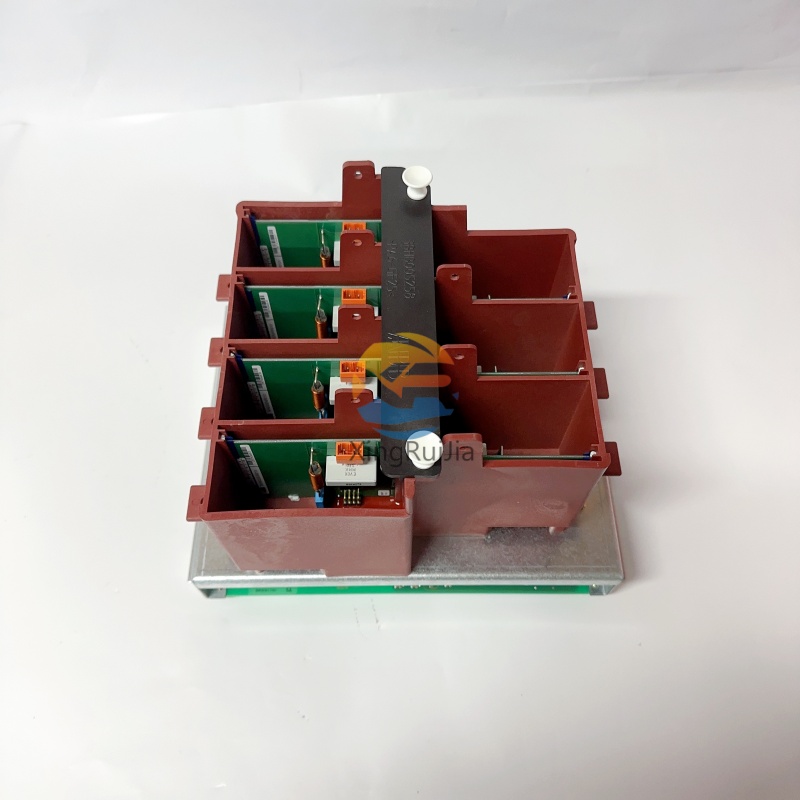

At its core is a powerful RISC processor designed for real-time control. It delivers exceptionally fast and, most importantly, predictable scan cycles. This determinism is critical for applications like turbine governor control, where a delayed response can lead to catastrophic consequences.

-

Benefit: Enables precise control of fast-acting processes, enhances overall process stability, protects multi-million dollar capital equipment, and ensures consistent product quality.

2. Seamless 1:1 Redundancy for Maximum Uptime:

The module is designed for high-availability operation. Two KUC755AE117 controllers can be configured in a hot-standby redundant pair. They run in perfect lockstep, with the standby unit continuously synchronized with the primary. Switchover in the event of a failure is instantaneous and bumpless.

3. Deep Integration with ABB Ability™ System 800xA:

This CPU is a native citizen of the System 800xA, the most comprehensive DCS on the market. It operates within a unified operational environment that integrates process control, safety, electrical systems, and asset management.

-

Benefit: Provides operators with a single, coherent view of the entire plant, simplifies engineering and maintenance, reduces system lifecycle costs, and enables data-driven decision-making.

4. Extensive Logic and Data Handling Capacity:

Equipped with substantial user memory, the KUC755AE117 can host very large and sophisticated application programs. This includes complex sequential control, advanced regulatory control loops, and data logging for historical analysis.

5. Comprehensive Diagnostic and Asset Management:

The module features advanced self-diagnostics and provides detailed health and status information. This data is accessible both via local LED indicators and through the engineering software, feeding into the 800xA's asset management system for proactive maintenance.

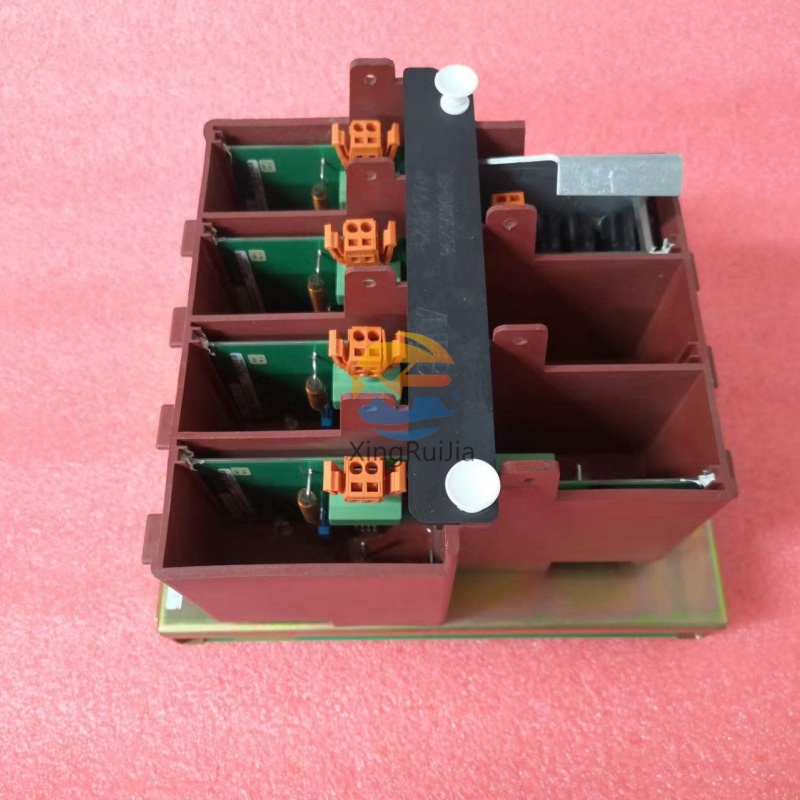

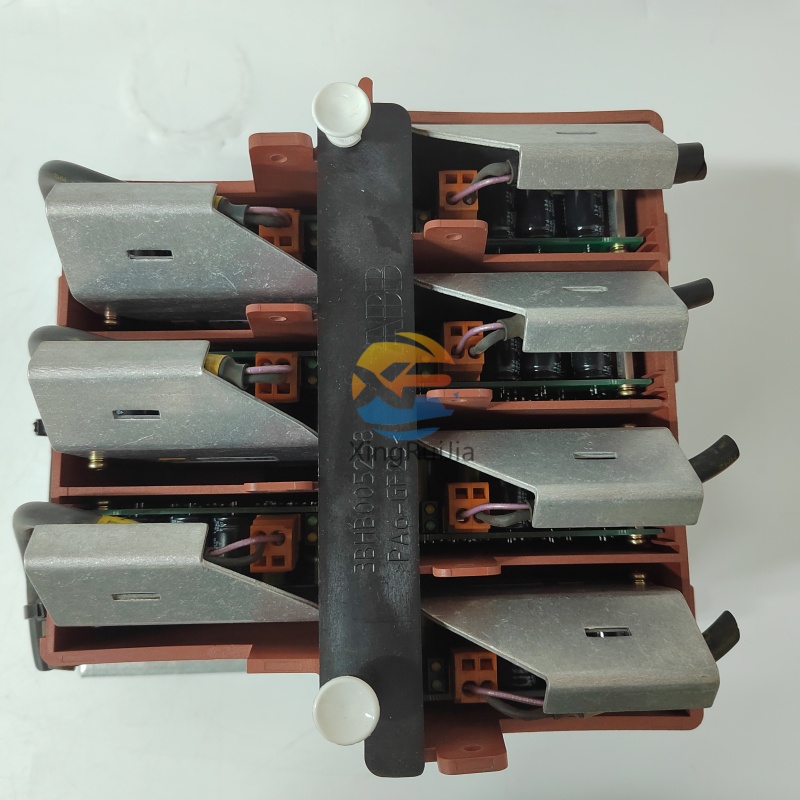

6. Robust Industrial Design for Harsh Environments:

Built to the highest industrial standards, this CPU is designed to perform reliably in environments with electrical noise, temperature fluctuations, and vibration, typically found in power generation and heavy industrial facilities.

Detailed Technical Specifications

For engineers, system integrators, and procurement specialists, here is a detailed technical breakdown of the ABB 3BHB005243R0117:

Primary Applications and Use Cases

The ABB KUC755AE117 is deployed in the most critical nodes of industrial automation infrastructure.

-

Gas & Steam Turbine Control: Managing the entire turbine lifecycle, from auto-start and synchronization to precise speed/load control and shutdown sequences. It handles critical loops for fuel, inlet guide vanes, and emissions control.

-

Compressor Control and Anti-Surge Protection: Implementing high-speed, complex algorithms to prevent compressors from entering the surge region, thereby protecting them from severe damage and ensuring pipeline or process stability.

-

Power Generation Systems: Serving as the key controller for boilers, governors, and balance-of-plant (BOP) systems in thermal, combined-cycle, and hydroelectric power plants.

-

Large-Scale Process Automation: Acting as the main process controller for complex, continuous processes in industries like oil & gas production, refining, and chemical processing, where high reliability is non-negotiable.

System Integration and Architecture

The KUC755AE117 is the centerpiece of a distributed control architecture.

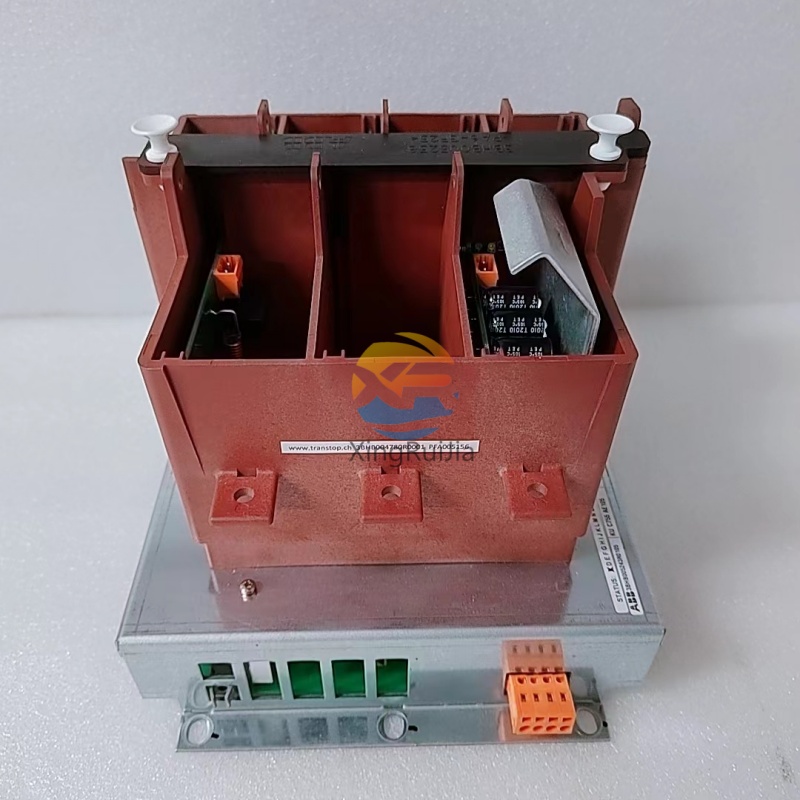

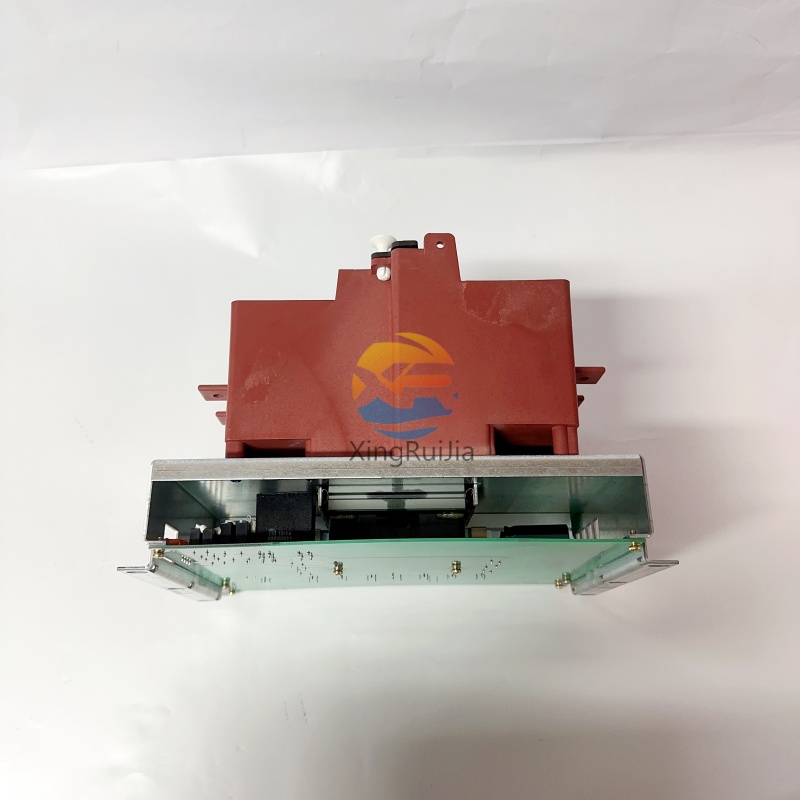

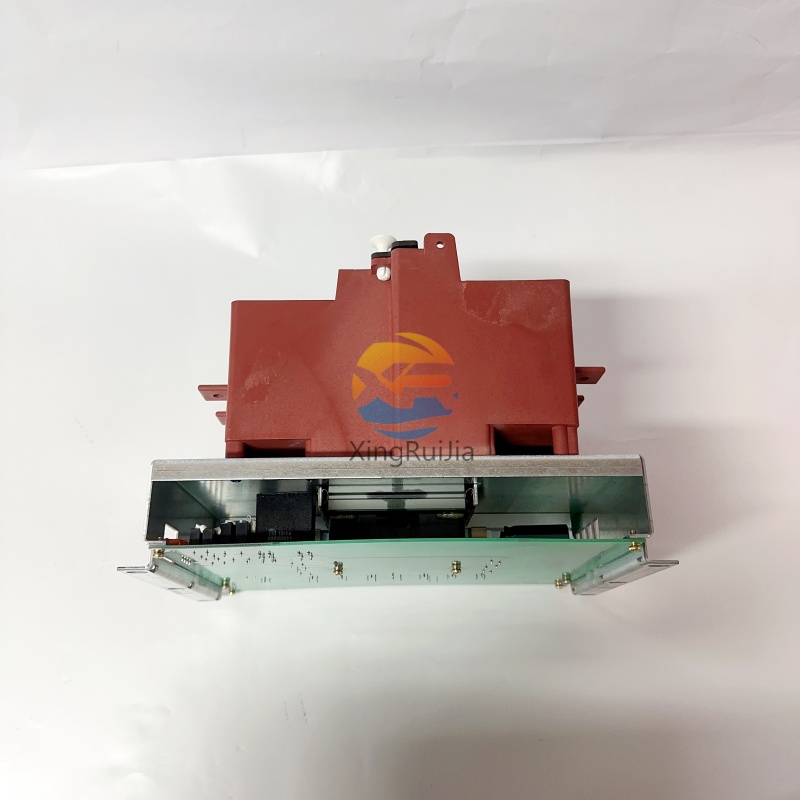

1. Physical Installation:

The module is installed in an ABB S800 I/O base unit (e.g., TU847, TU844). It draws power from the backplane and communicates with other modules via the internal TDM bus.

2. Network Topology:

The CPU communicates with distributed S800 I/O clusters using the MasterBus 300 (MB300) fieldbus, a high-speed, deterministic network. This allows for a distributed architecture where I/O racks are placed close to the field devices, minimizing analog signal wiring.

3. Redundant Configuration:

In a redundant setup, two KUC755AE117 modules are installed in a special redundant base unit. They are connected by a high-speed synchronization fiber-optic link. The primary and standby units are configured and programmed as a single logical entity.

4. Engineering and Configuration:

The entire system is configured using ABB's powerful Control Builder M engineering tool. This integrated software provides a single environment for:

-

Hardware configuration

-

Application programming using IEC 61131-3 languages (FBD, ST, SFC)

-

System diagnostics and troubleshooting

-

Documentation management

KUC755AE117 within the ABB Controller 800xA Family

The KUC755AE117 is part of a family of CPUs, each optimized for different performance requirements. When compared to other models like the KUC755AE105 or KUC755AE106, the "AE117" variant typically represents a specific performance tier, potentially featuring:

-

Enhanced Processing Speed: For applications requiring the absolute fastest possible scan times.

-

Larger Memory Capacity: To accommodate extremely large and complex control programs or extensive data logging.

-

Specialized Firmware: Including optimized function blocks for specific industries like turbine control.

For any project, it is crucial to consult the official ABB technical documentation to select the CPU model that precisely matches the application's performance, memory, and functional safety requirements.

Why Choose the ABB KUC755AE117? The Strategic Advantage

Selecting the KUC755AE117 is a strategic decision that pays dividends throughout the asset's lifecycle.

-

Unmatched Proven Reliability: The Advant Controller platform has a decades-long track record in the world's most critical installations. Its reliability is a known quantity, reducing project risk.

-

Future-Proof Platform Investment: As a core component of System 800xA, it is supported by ABB's long-term product lifecycle strategy, ensuring support, spares, and migration paths for decades.

-

Global Technical Support: ABB's worldwide service network provides expert support, from initial commissioning and training to 24/7 emergency service and lifecycle management.

-

Optimized Total Cost of Ownership (TCO): The high initial investment is offset by near-zero unplanned downtime, reduced maintenance costs, and extended system longevity, resulting in a superior TCO compared to less robust solutions.

Sourcing, Authenticity, and Lifecycle Support

The ABB KUC755AE117 3BHB005243R0117 is a critical component. Sourcing it requires diligence to ensure system integrity.

-

Authenticity is Paramount: Insist on genuine ABB parts. Counterfeit modules can cause unpredictable failures, pose safety risks, and void system warranties.

-

Condition Clarification: Verify if the unit is new, ABB-refurbished, or tested-used. Request documentation of testing and provenance.

-

Supplier Verification: Partner with established, reputable suppliers who specialize in industrial automation components and can provide technical data and support.

-

Compatibility Assurance: Ensure the module is compatible with your existing S800 I/O hardware (base units, power supplies) and firmware versions.

ABB provides comprehensive lifecycle support for this product family, including technical documentation, repair services, and migration advisory services.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between the KUC755AE117 and other KUC755AE models?

A: The differences typically lie in processing speed, memory capacity, and potentially specialized firmware. The AE117 is generally a high-tier model suited for the most demanding applications. Always refer to the official ABB technical data sheets for a precise comparison.

Q2: Can the KUC755AE117 be used for safety instrumented functions (SIF)?

A: While it is an extremely reliable controller for basic process control (BPCS), it is not typically certified as a Safety Instrumented System (SIS). For safety functions, a dedicated system like ABB's Safeguard 800F is used, which can integrate seamlessly with the 800xA platform.

Q3: What software is required to program this controller?

A: ABB's Control Builder M is the standard engineering tool for configuring, programming, and maintaining the KUC755AE117 and the entire 800xA system.

Q4: How is the redundant switchover initiated?

A: Switchover is fully automatic. It is triggered by the standby module's detection of a fault in the primary module (e.g., hardware failure, loss of communication). The transfer is designed to be seamless and does not interrupt the control process.

Q5: Our facility has an older ABB Advant OCS system. Is this controller a suitable upgrade?

A: Absolutely. The System 800xA, with controllers like the KUC755AE117, is the strategic successor to the Advant OCS. ABB provides well-established tools and services for migrating application logic and configuration to the modern platform.

Conclusion: The Definitive Choice for Critical Control

The ABB KUC755AE117 3BHB005243R0117 is not merely a product; it is the embodiment of control system resilience and performance. It is engineered for those who understand that the cost of failure far outweighs the investment in quality. By specifying this controller for turbine control, critical compressor applications, or complex process logic, you are investing in the safety, availability, and efficiency of your most vital industrial assets.

It is the benchmark against which other high-availability controllers are measured.

Call to Action:

Ensure the integrity of your control system with a genuine ABB component. Contact us today for a competitive quotation, detailed technical documentation, and expert consultation on the KUC755AE117. We provide guaranteed authentic components and the technical support to ensure successful integration and operation.

Sweden

Sweden

Sweden

Sweden